Demystifying Fiber Cutting Machine Prices Understanding Factors and Trends in the Metal Fabrication Industry

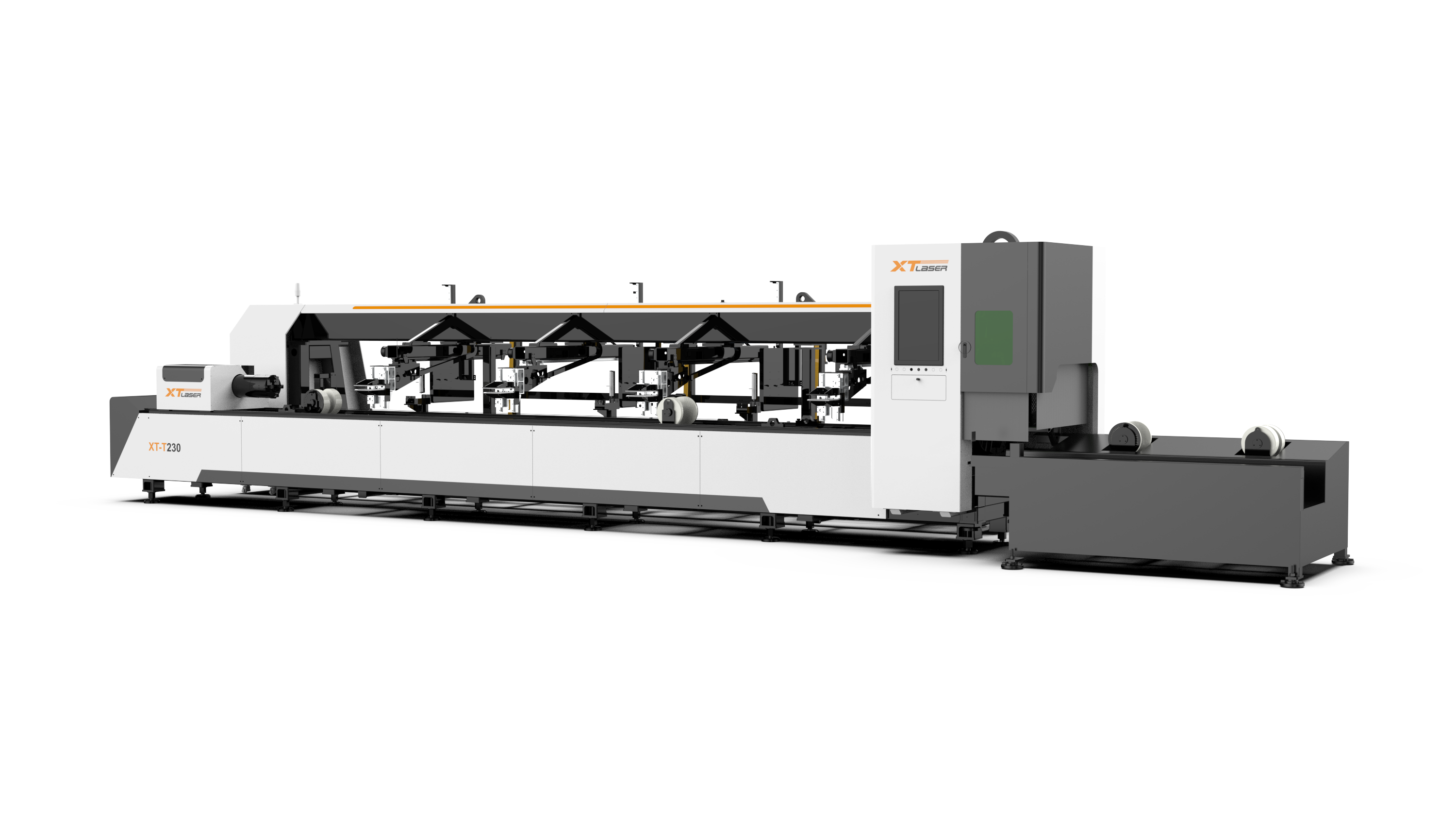

The metal fabrication industry has seen significant advancements in technology, with fiber cutting machines gaining popularity for their precision, speed, and versatility. If you're considering investing in a fiber cutting machine for your business, one crucial aspect to consider is the price. With the current search hotspots revolving around fiber cutting machine prices, it's essential to understand the factors and trends that influence the cost of these machines.

Factors Affecting Fiber Cutting Machine Prices

Several factors can impact the price of a fiber cutting machine, and it's crucial to be aware of them when evaluating different options. Here are some key factors that can affect the cost of a fiber cutting machine:

Power Output: The power output of a fiber cutting machine is a significant factor in determining its price. Higher power machines can cut through thicker and tougher materials, but they tend to be more expensive compared to lower power machines.

Cutting Area: The cutting area or working size of the machine can also impact its price. Larger cutting areas typically come with higher price tags, as they offer more versatility and flexibility in handling different sheet sizes and shapes.

Brand and Reputation: The brand and reputation of the manufacturer can also influence the price of a fiber cutting machine. Established brands with a reputation for quality and reliability may command higher prices due to their brand value.

Automation Features: Automation features, such as automatic material loading and unloading systems, can significantly impact the price of a fiber cutting machine. Machines with advanced automation capabilities tend to be more expensive, but they can also increase productivity and efficiency in the long run.

Software and Technology: The software and technology used in a fiber cutting machine can also affect its price. Machines with advanced software, user-friendly interfaces, and cutting-edge technology may come with a higher price tag, but they can offer enhanced performance and ease of use.

Trends in Fiber Cutting Machine Prices

In addition to the factors mentioned above, there are also some trends in fiber cutting machine prices that are worth considering. Here are a few current search hotspots related to fiber cutting machine prices:

Competitive Market: The metal fabrication industry is highly competitive, and this can impact the prices of fiber cutting machines. As more manufacturers enter the market and competition increases, it can lead to more competitive pricing, with manufacturers offering competitive deals and discounts to attract customers.

Technological Advancements: With constant advancements in technology, fiber cutting machines are becoming more efficient, precise, and versatile. However, these advancements can also impact the prices of the machines. Newer technologies and features may come with higher costs, but they can also offer improved performance and capabilities.

Market Demand: Market demand for fiber cutting machines can also influence their prices. High demand for these machines can drive up prices due to increased competition and limited supply, while low demand may result in lower prices as manufacturers look to attract customers.

Conclusion

When evaluating fiber cutting machine prices, it's crucial to consider the various factors and trends that can influence the cost. Power output, cutting area, brand reputation, automation features, software and technology are some of the key factors that can affect the price of a fiber cutting machine. Additionally, understanding the current search hotspots and market trends can provide valuable insights into the pricing dynamics of the metal fabrication industry. By carefully considering these factors and trends, you can make an informed decision and choose a fiber cutting machine that aligns with your business needs and budget.